Generation-01

⚪ 300 Wh/kg energy density.

⚪ Charging Time - 60 Minutes.

“Revolutionising Lithium Batteries with advanced Silicon Anodes"

"Silicon is regarded as a most promising anode for next-generation lithium batteries and it can increase the energy density of lithium batteries 2x with extraordinary 10x anode energy density compared to graphite anode."

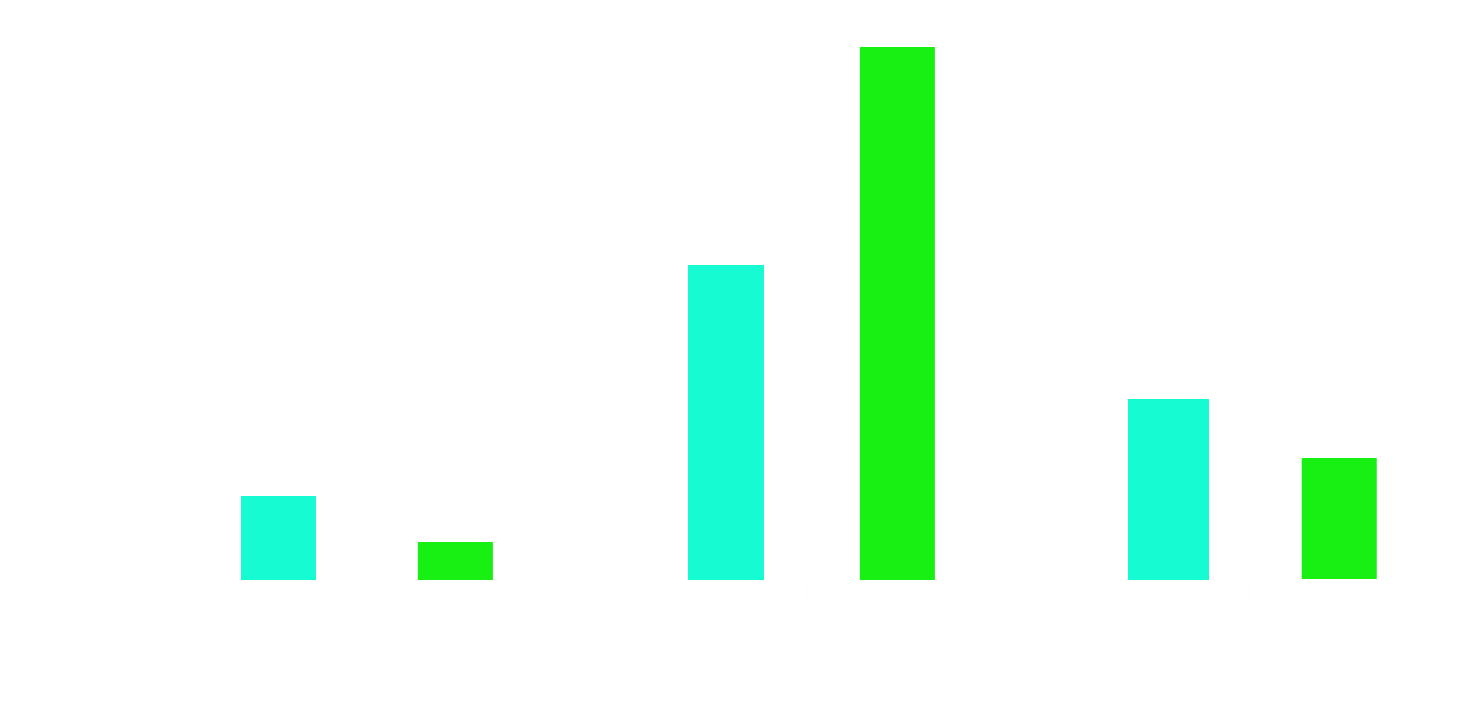

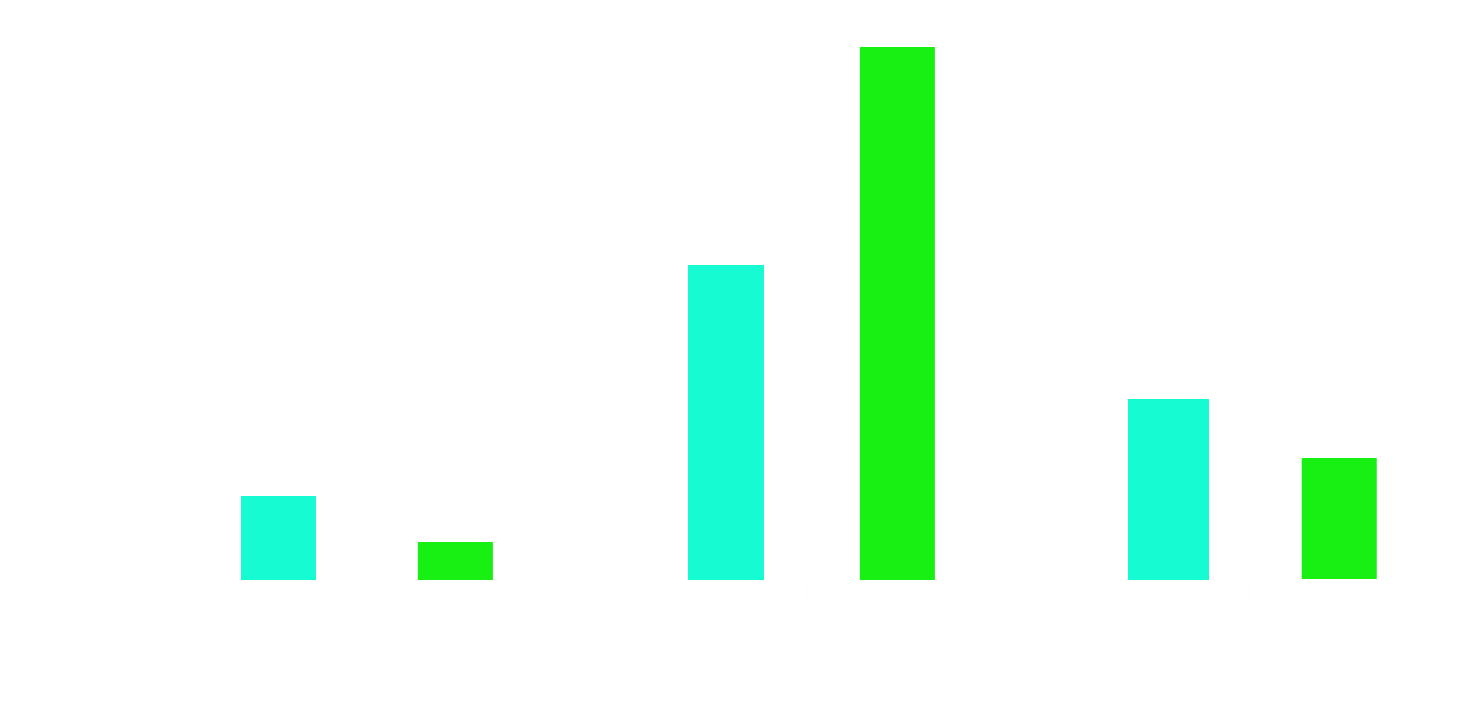

Volumetric energy density (mAh/cm3)

Si expands during charging and shrinks during discharging, which makes the mechanical and electrical integrity weak and results in poor cycling performance.

Si volume expansion 400%

The key to making Si anode-based lithium batteries and achieving higher cycle life lies in restricting this huge volume expansion during operation. We, at Cellark, have developed a porous micro-size lithium anode material, which not only takes care of huge volume expansion but also restricts the amount of oxide formation over silicon surface, thus improving the mechanical and electrical integrity and ensuring higher cycle life during operation.

(2).jpg)

Taking advantage of high silicon energy density the cell developed with porosil anode material provides much higher capacity in the same volume than the graphite anodes, our porosil anode gives >550mAH/gm of energy density.

(2).png)

Silicon anode suffers from huge volume expansion which reduces the life of the battery. Our innovative porosil anode solves this problem with our porous silicon morphology. The crux of the innovation lies in the science of selective leaching of Al-Si and its galvanic coupling.

.png)

Our proprietary method to produce Si and graphite composite with suitable carbon coating ensures proper bonding of graphite and silicon and higher life of the battery.

(1).jpg)

With the specific capacity increased, the anode material needed to fabricate cell is reduced by 50%, which, further brings down the cost of the cells.

Volumetric energy density (mAh/cm3)

Si expands during charging and shrinks during discharging, which makes the mechanical and electrical integrity weak and results in poor cycling performance.

Si volume expansion 400%

The key to making Si anode-based lithium batteries and achieving higher cycle life lies in restricting this huge volume expansion during operation. We at Cellark have developed a porous micro size lithium anode material, which not only takes care of huge volume expansion but also restricts the amount of oxide formation over silicon surface, thus improving the mechanical and electrical integrity and ensuring higher cycle life during operation.

(2).jpg)

Taking advantage of high silicon energy density the cell developed with porosil anode material provides much higher capacity in the same volume than the graphite anodes, our porosil anode gives >550mAH/gm of energy density.

(2).png)

Silicon anode suffers from huge volume expansion which reduces the life of the battery. Our innovative porosil anode solves this problem with our porous silicon morphology. The crux of the innovation lies in the science of selective leaching of Al-Si and its galvanic coupling.

.png)

Our proprietary method to produce si and graphite composite with suitable carbon coating ensures proper bonding of graphite and silicon and higher life of the battery.

(1).jpg)

With the specific capacity increased, the anode material needed to fabricate cell is reduced by 50%, which, further brings down the cost of the cells.

⚪ 300 Wh/kg energy density.

⚪ Charging Time - 60 Minutes.

⚪ 350 Wh/kg energy density.

⚪ Charging Time - 40 Minutes.

⚪ 450 Wh/kg energy density.

⚪ Charging Time - 20 Minutes.

⚪ 300 Wh/kg energy density.

⚪ Charging Time - 60 Minutes.

⚪ 350 Wh/kg energy density.

⚪ Charging Time - 40 Minutes.

⚪ 450 Wh/kg energy density.

⚪ Charging Time - 20 Minutes.

Current Graphite Anode Lithium Batteries

Current Lithium Technology

Porosil Lithium Technology

Current Graphite Anode Lithium Batteries

Current Lithium Technology

Porosil Lithium Technology